Introduction to Online Trading of Moku.com

On May 20, 2022, Moku.com online trading project was officially launched. Transfer the transaction of grinding enterprises from offline to

On May 20, 2022, Moku.com online trading project was officially launched. Transfer the transaction of grinding enterprises from offline to

–The Fourth Phase of Abrasive and Abrasive Tools Training Program of Materials School of Henan University of Technology Successfully Concluded

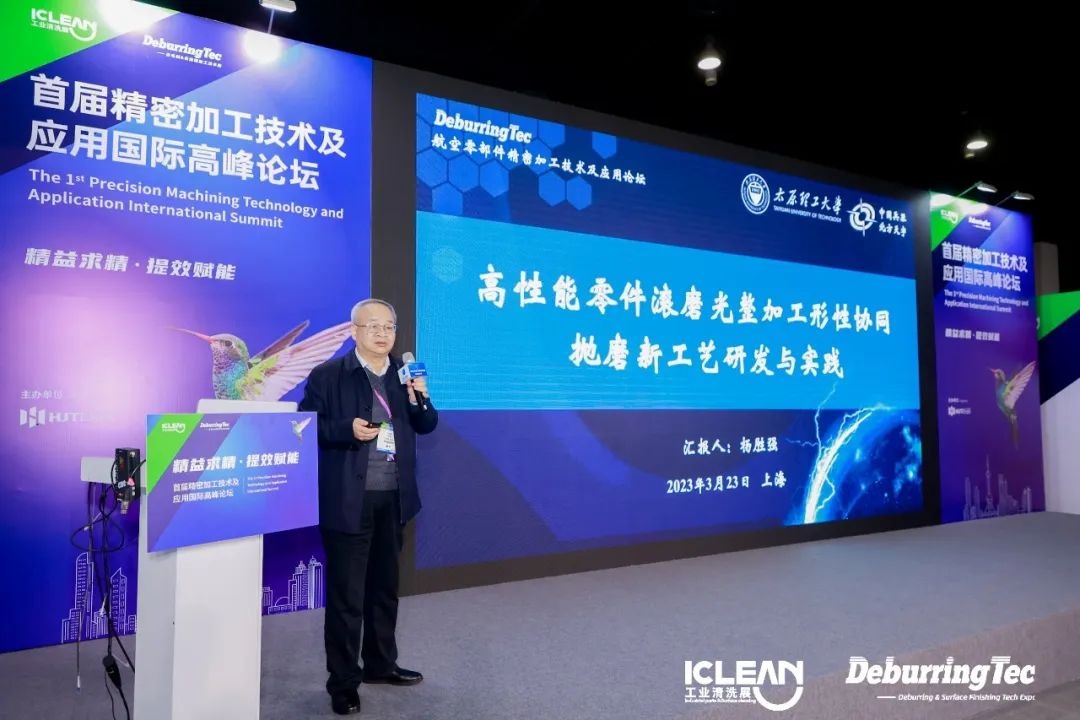

MK ONLINE TRADING May 20 Moku Online Transaction Officially Launched Yang Heng, CEO of Moku.com, said that the online