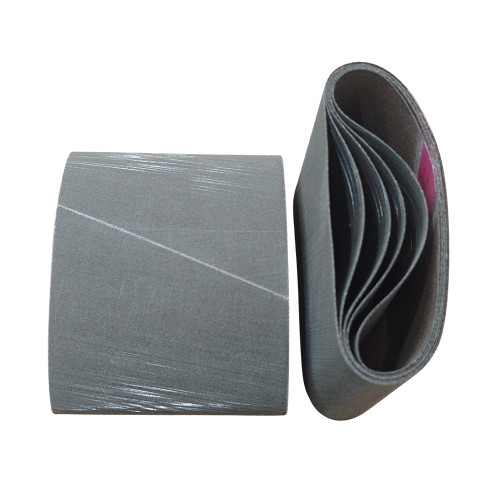

PYTAMID™ Pyramid Structured Abrasive

Abrasivestocks PYTAMID Sanding Belts are built with PYTAMID™ Pyramid Structured Abrasive, featuring precision micro-structured abrasive minerals formed in uniform pyramid-shaped layers. As each layer wears away, fresh cutting points are continuously exposed—delivering consistently sharp cutting action, predictable finishing results, and exceptionally long belt life.

This makes PYTAMID belts ideal for demanding applications where accuracy, repeatability, and surface consistency are essential—including stainless steel fabrication, carbon steel polishing, aluminium finishing, woodworking, automotive refinishing, stone work, and glass processing.

Available Sizes

Our PYTAMID belts are available in the most commonly used industrial dimensions:

-

915 × 50 mm

-

760 × 40 mm

-

762 × 25.4 mm (1″ × 30″)

-

533 × 30 mm

-

283 × 100 mm

➡ Custom sizes available on request to match special machinery and production needs.

Available Grades (New Marking: P-Grit (A-Grade))

We supply the full PYTAMID structured abrasive range with clear P-grit (A-grade) reference:

-

P120 (A160) – Heavy material removal

-

P180 (A100) – Intermediate cutting & surface blending

-

P240 (A80) – Transition cutting & surface conditioning

-

P320 (A65) – Controlled cutting & consistent scratch

-

P400 (A45) – Fine finishing

-

P800 (A30) – Extra-fine finishing

-

P1500 (A16) – High-refinement finishing

-

P2000 (A6) – Ultra-fine finishing / pre-polish

-

P3000 (A5) – Higher-grade pre-polish

-

P5000 (A3) – Ultra-fine finishing / mirror-prep

Ultra-fine grades (#8000 and #10000) are available upon request.

This spectrum supports everything from aggressive stock removal to extremely refined finishing.

Key Features & Benefits

-

PYTAMID™ Pyramid Structured Abrasive – self-renewing layers deliver constant cutting performance

-

Extended belt life – fewer changeovers, lower downtime and cost

-

Stable belt construction – smooth tracking and vibration-free operation

-

Full range from P120 (A160) to P5000 (A3) – from initial grind to mirror-prep finishing

-

OEM & bulk supply support – ideal for industrial users and equipment manufacturers

Applications

-

Stainless steel & metal fabrication – grinding, finishing, surface refinement

-

Aluminium & non-ferrous metals – uniform finishes with reduced smearing

-

Woodworking – smooth, clean results on hardwoods and softwoods

-

Automotive refinishing – paint removal, rust cleanup, panel preparation

-

Stone & glass processing – precise finishing with minimal defects

Customization Options

✔ Standard sizes + full custom manufacturing

✔ Full grade range: P120 (A160) to P5000 (A3)

✔ OEM branding available

✔ Local Australian stock with fast delivery